Northern Gas Networks & Synovate are undertaking a highly collaborative project, working with the EIC and a consortium of innovators, including The Technology Partnership (TTP) and the University of Leeds, to develop ‘LeakVISION’- a detection sensor that will internally detect, locate and quantify pipe damage / deterioration.

We sat down with Simon Langdale, Engineering Manager at Synovate and Thomas McPherson, Operational Project Manager at Northern Gas Networks to tell us more.

Tell me a bit about the project

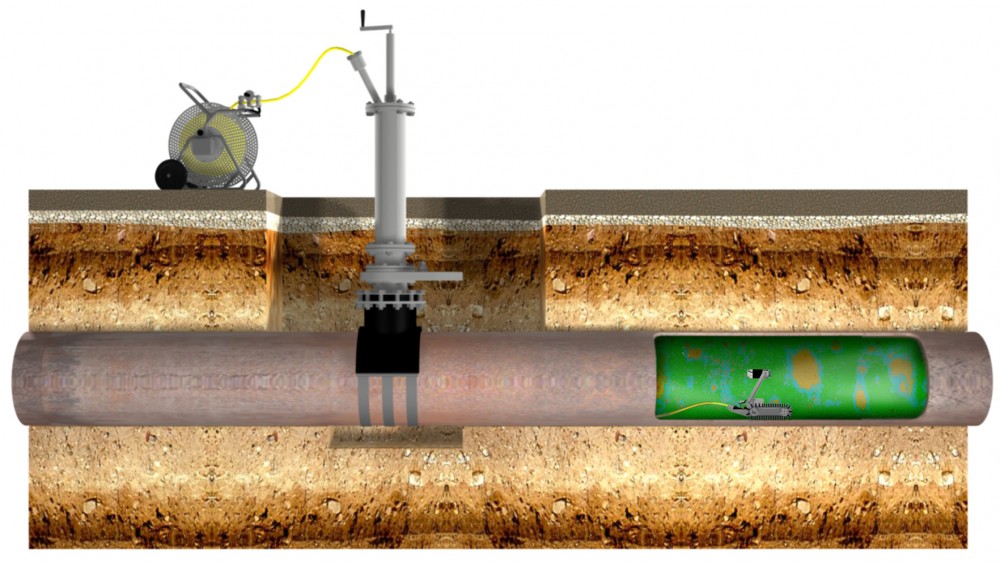

Thomas: LeakVISION is an in-pipe leakage detection sensor, mounted to a robot base/push rod camera system. The system is used for the inspection of in-pipe features to indicate the presence of leakage from pipeline features, such as joints, connections and defects. This project builds on the successful and previously completed NIA project delivered by Cadent and additional, independent work by Synthotech Ltd.

The technology will be developed using a community of project partners, with Synovate Ltd as lead in the technology development. The Technology Partnership (TTP) will develop scientific understanding of the mechanics that underpin the process. Key to the development is a detailed understanding of the computational fluid dynamics (CFD), allowing for optimisation and detailed design of the system.

What is the main challenge that LeakVISION looks to address?

Thomas: Currently, the method of detecting the location of leaks within gas networks is known as ‘above ground bar holing’. This technique poses a challenge for the networks as the method can often produce inaccurate results, causing unnecessary excavation and reinstatement works to be carried out. The application of the technique is also physically demanding and can cause unwanted strains or injury to operatives performing the work.

Can you tell us a bit more about the solution, ‘LeakVISION’ and how it will look to improve the challenge of leakage detection?

Simon: LeakVISION aims to increase productivity by locating underground leakage both reactively and proactively. The complex underground gas network creates a challenging environment to find the exact location of underground leakage. The LeakVISION technology uses machine learning to analyse and highlight leakage by directly scanning the pipeline, pinpointing the area. This then allows for improved decision making and very precise targeted remediation, reducing the impact to the environment and road users by preventing and minimising excavation.

What benefits could LeakVISION have for gas networks?

Simon: One of the main benefits is a reduction in excavation, which will reduce environmental impacts, costs and minimise traffic disruption. The data collected will allow for improved decision making and can support the assessment of the suitability of the gas network for the conversion to transporting hydrogen.

How will improved detection of leakage benefit customers?

Simon: The LeakVSION solution gives utilities networks a powerful tool to identify and locate leakage. This means that gas customers can be assured that the underground pipelines are safely maintained and that they can be evaluated for transition to hydrogen blending. The proactive application of the technology means less gas escapes and a continued excellent safety record.

Thomas: Improving our methods of leak detection will also reduce the number of excavation and reinstatement works being carried out, meaning less disruption for our customers.

How does this project contribute towards the challenge of meeting net zero targets?

Thomas: By locating and sealing leakage points, our contribution to greenhouse gas emissions and climate change greatly reduces. If NGN can strive to make projects like LeakVISION a success it will truly drive our ability to help hit ‘net zero’.

Simon: The project supports the transition to net zero by creating a technology that is capable of detecting leakage and inspecting pipelines. This will be key as we move over to using the new gases that will be necessary in order to meet net zero. Analysing the existing pipelines and checking if they are suitable for the transition will be detrimental to the success of the switch of gases. It will also be important to inspect the pipes regularly in order to monitor the impacts that these gases have on the network.

LeakVISION is a highly collaborative project - how does this project demonstrate the importance of collaboration within the world of innovation?

Thomas: Working together is key to evolving the world of innovation. Without the ability to share and use ideas and solutions, we will never move forward quickly to improve our networks and the way we operate.

What is the current status of the project/where is the project up to?

Simon: We are currently researching the sensing packages using computational fluid dynamics and analytical models. This will help us to design the most compact solution possible, meaning that we will be able to inspect a wider range of pipe sizes.

Thomas: The sensor is being calibrated at TTP, who have been impressed at how accurate the real-world technology is when compared to the design models.

What’s next?

Simon: The next stage of the project is to develop detailed engineering designs and prototypes. Once these have been manufactured, they will be thoroughly tested before they are deployed into the UK gas network to search for and locate any potential leakage.

Thomas: We will also be inviting a group of experienced and knowledgeable members of NGN to cast their eyes and thoughts on the LeakVISION project and help shape the process of moving the project to field trials.

Find out more about the project here.

Explore our latest opportunities to find out how you could work with our network partners here.