Northern Gas Networks (NGN), the gas distributor for the North of England, has begun trialling a new ground protection board to reduce pavement damage during maintenance and installation activities.

Facilitated by the EIC, NGN has teamed up with Leeds based plastics engineering and supply company, Engineering Plastic Supplies Ltd to conduct a four-week trial of their environmentally friendly, lightweight, robust and recyclable solution to pavement protection.

Activities which require excavation and then backfilling or spoil removal on completion often result in damage to pavements – resulting in further inconvenience to the public, complaints from customers and local authorities, and increased costs due to repair requirements.

NGN’s existing solution is visqueen, a lightweight plastic sheeting which is not currently widely recycled.

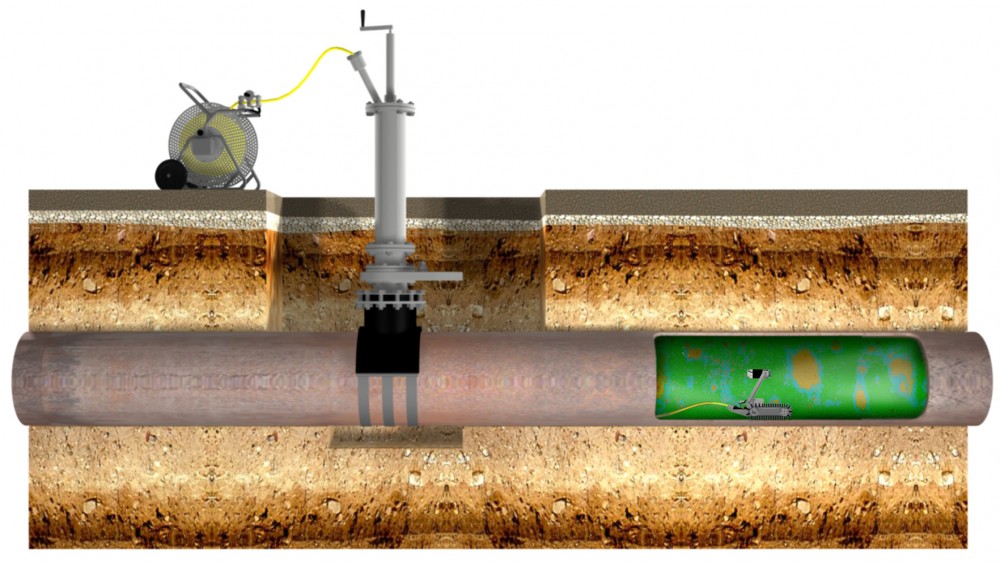

Engineering Plastics’ Private Works Ground Protection (PWGP) solution is an environmentally friendly, reusable board that will protect the ground from all maintenance and installation activities as well as providing a temporary, safe ‘glow in the dark’ walkway for customers where necessary.

Jeff Oliver, Regional Reinstatement Manager at Northern Gas Networks said:

“I am passionate about seeing this trial develop from concept to completion. Our focus around operational demands has always been to prevent customer complaints, highway defects and reduce our environmental impact – all of which this product could potentially offer benefits on. Our current use of visqueen has positives and negatives but the business’ aim to be more sustainable and environmentally friendly means we are proactively seeking better solutions.”

Andy Edwards, Product Development Manager at Engineering Plastic Supplies Ltd said:

“At EPS we work on projects that help utilities engineers reduce their impact whilst on site. The Private Works Ground Boards are a simple yet effective solution for improving housekeeping and reducing potential damage to residents and business owner’s properties.

“Flexible, strong, recyclable and reusable, the covers are designed to withstand continual use and can be jet washed to remove excavated materials.

“As an SME we are always looking for innovations that help larger organisations work more efficiently with the environment and customers in mind.”

David Turner Bennet, Innovation Engineer at the EIC said:

“I am excited to co-ordinate this trial between NGN and EPS. Through the EIC, Northern Gas Networks can trial market-ready products which often act as ‘quick hits’ in areas such as customer satisfaction, safety or efficiency. This is a potentially low effort/high impact product which aims to prove its effectiveness in protecting a customer’s property within NGN’s operational demands. I look forward to the completion of the trial and reviewing its success.”

NGN’s trial of the product highlights their commitment to a cleaner and greener environment as part of their environmental strategy. A successful trial and subsequent implementation will not only increase customer satisfaction, it will be yet another step in the right direction in reducing their carbon footprint.