- Impact : Disruptive

- Key benefits/themes : Customers, Environmental, Financial

- Project partners : Kinectrics UK’, UK Power Networks and Northern Powergrid

The Challenge

There are more than 4,750km of Fluid Filled Cables (FFC) across the UK electricity network, dating as far back as the 1930s. All these cables are insulated with tightly-lapped cellulosic paper, impregnated with a low viscosity dielectric fluid that enhances the insulation system electrically and thermally.

As FFC networks age, if the cable sheath or accessories are damaged, the fluid leaks out from the insulation layer into the surrounding environment. In the UK, it’s estimated that approximately 375,000 litres of fluid is lost from FFCs in this way annually.

The Solution

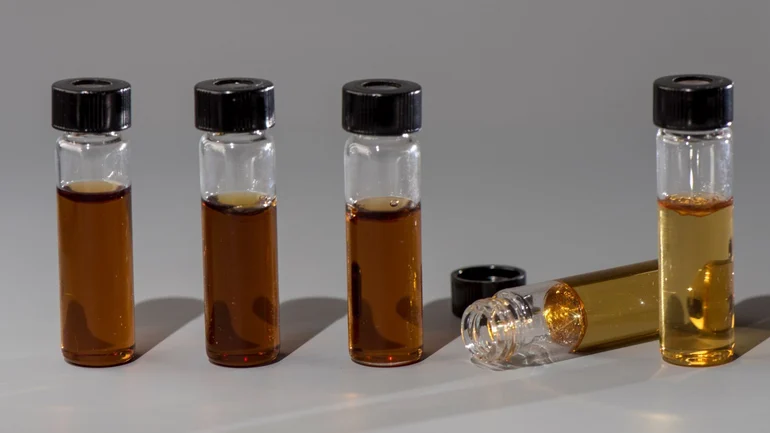

The aim of this project was to develop a Self-Healing Fluid (SHF), known as Anagen, which would help to address this challenge.

During normal operations, Anagen functions as an insulation oil within the cable system.

However, in the event of an oil leakage caused by cable damage, Anagen will crosslink to form a solid mass, sealing the defect. This stops the leak and prevents further leaks down the cable, which protects the local environment and the cable itself.

“NIA funding has been essential in enabling this innovation as it would have taken significantly longer without it, if not been impossible to achieve. At the end of the project, UKPN aims to adopt this technology into our operational processes, meaning the highest TRL of 9 will have been achieved.”

Robert Davies , Innovation Engineer, UKPN

Project Partners

The first two phases of the project were delivered by SME innovator, Gnosys Global, which has since been acquired by Kinectrics UK.

Developmental activities in the current phase of the project are being collaboratively funded by UK Power Networks and Northern Powergrid via the Network Innovation Allowance (NIA) framework. Thanks to this support, the networks have worked with the innovator to advance the solution from Technology Readiness Level (TRL) 2 to 8.

The EIC has facilitated and supported all three phases of the project, over a period of over 10 years, from project plan development, legal contracting and project delivery, all in accordance with NIA governance.

The EIC also supported engagement with test houses both in the UK and abroad to develop a testing regime to prove the solution. This was essential in refining project requirements and identifying the most suitable test house.

The Project

The first two project phases successfully identified, developed and evaluated new self-healing polymers that could mitigate leakages, one of which was Anagen. They also involved controlled testing to evaluate the application of Anagen within cable systems and refine its production processes.

The phase 3 project seeks to advance the deployment of Anagen in FFC networks in the UK, which includes introducing it into cables in the same way as a standard cable oil, i.e. as a top-up fluid.

Testing is planned in to ensure that the formulation of Anagen is electrically compatible with existing cable systems. Testing will also help develop greater understanding of Anagen’s operation and handling. Field trials will also be completed in circuits selected by the networks.

It’s expected that this project will enable a greater understanding of how cable oil flows, mixes and dilutes with Anagen within the cable system. This will allow Anagen to be effectively deployed at leak sites to facilitate repairs and containment of cable oil.

- Customers : Potential to reduce the number of disruptions experienced by customers as a result of repair and maintenance activities.

- Financial : Reduction in the number of leak repair activities currently undertaken. It’s estimated that the average oil repair cost for a single leak is around £45K while cable replacement costs are approximately £500K per km.

- Environmental : Reduction in the loss of cable fluid into the environment as a result of containment enabled by the Anagen solution.

“Anagen™ arose from a challenge set out by UK network operators to reduce leakage from fluid filled cables. Over the course of three NIA-funded projects (lasting over ten years), Anagen™ was developed from laboratory scale trials into a tangible solution that is produced on the multi-tonne scale and deployed in cables over 1km in length. NIA funding has been crucial to this achievement and it allows network operators to assign funds to the development of innovative solutions to help solve intractable problems.”

Anuj Nayyar – Business Development Director – Kinectrics UK

Next steps

This solution is applicable to all Distribution Network Operators (DNOs), with the potential for application by transmission network operators too.

Provided that the project and subsequent network trials are successful, the Anagen fluid could be introduced into FCC networks in the UK. Learnings to-date have validated Anagen’s potential as a cheaper alternative to repairing or replacing cable sections with leakages.